| |

| |

|

The

1911 Tanto Extractor

|

|

(

A Dave Lauck design - patent pending )

|

|

| Those

who study firearm designers and their achievements will

no doubt recognize the name John Moses Browning.

John Browning is recognized as a genius of firearms design.

This is especially true when you consider the era in which

he worked, long before the CAD drawings and CNC machine

centers we are familiar with today. |

|

| The

1911 autopistol is one of John Browning's long lasting

designs. It continues to be extremely popular today, especially

among highly skilled and knowledgeable shooters. Many

shooters have their own individual reasons for choosing

the 1911 design, but the general reasoning normally revolves

around the fact that the 1911 is a very user friendly

design which leads to high performance shooting when used

by properly trained shooters. The fact that it has a manual

safety, which has to be manipulated before it will fire,

is also viewed as a highly desirable feature by police

officers and defensive shooters who have the foresight

to consider gun grab situations. |

|

| We

now have decades more experience, and many millions more

rounds down range with the 1911 than its original designer.

This has allowed for extensive evaluation of the 1911

design and for improvements to be made where they were

obviously needed. Things like improved sights and upswept

beavertail grip safeties are now widely used and accepted

as improvements in the 1911 design. |

|

|

|

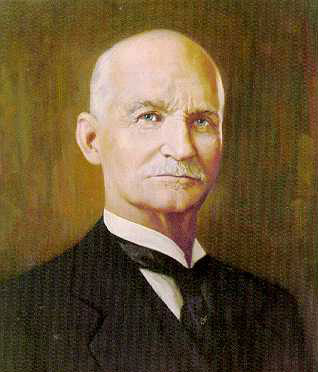

| John

Moses Browning |

|

|

|

| Another

item which has been extensively evaluated in the 1911

is it's internal extractor. |

|

| The

operation of this device is often misunderstood, even

by experienced 1911 shooters. Misunderstanding the extractors

method of operation has led to many damaged and malfunctioning

1911s. |

|

| The

1911 operates with what has become known as "controlled

feed". In other words, the cartridge slides under

the extractor hook once it is released from the feed lips

of the magazine, thus it is then controlled by the extractor

during much of the feed cycle. |

|

| The

1911 extractor hook does not routinely snap over the base

of the cartridge as many people seem to believe. |

|

|

|

| When

a 1911 autopistol is properly constructed, and John Browning's

original internal extractor design is correctly installed,

it is not at all uncommon for the pistol to fire many

thousands of rounds without malfunction, with only routine

maintenance. This is of course when the pistol is operated

properly, i.e. cartridges are fed from the magazine into

the chamber. |

|

| Problems

can occur immediately, or over time when this important

1911 operational rule is not followed: Always load

the chamber by cycling a cartridge into the chamber from

a loaded magazine. |

|

| When

the 1911's slide is locked open and a cartridge is dropped

directly into the chamber, then the slide is |

|

|

| snapped shut,

it forces the extractor to operate in a manner which it

was not designed to. Instead of allowing the cartridge

to slide behind the extractor's hook from the underside,

it forces the extractor's blunt leading nose to impact

the rear of the cartridge at high speed. This can cause

the extractor hook to fracture and snap off, thus causing

an immediate problem. |

|

|

|

| Problems

can also develop over time when an operator improperly

loads the pistol as part of his loading routine. Repeatedly

impacting the extractor's blunt nose against cartridge

bases, and not snapping off the hook, causes the hook

to be forced outward and around the cartridge bases. This

can eventually lead to breaking the extractor hook, and

almost always leads to ruining the extractor's adjustment.

A broken extractor hook obviously will not allow the extractor

a means to pull the fired case out of the chamber. A misadjusted

extractor may also fail to extract. It may also cause

stove piping, case crushing, and feeding failures. Bottom

line is that a 1911 extractor plays a critical role in

the operation of your pistol. |

|

| Warning:

Anytime you snap a 1911 extractor over the base of a chambered

case, intentionally or by mistake, with any extractor

design, you should have the pistol examined by a competent

1911 pistolsmith before using the pistol for serious purposes. |

|

|

|

|

|

| Firearms

instructors and 1911 "authorities" who don't

understand the mechanical operation of the pistol often

make the problem worse by providing a poor example to

student shooters by misloading their own pistols in front

of a class. It is also not uncommon for firearms instructors

to insist students rack their 1911 slides/extractors over

chambered cases during malfunction clearance drills. This

commonly results in broken extractors in the class, or

students leaving with a misadjusted extractor in their

defensive pistol, a problem waiting to happen. |

|

| OK,

we understand the 1911's chamber needs to be loaded by

slide cycling a cartridge into the chamber from the magazine

to avoid extractor damage. We will always do it this way

and avoid problems. The theory sounds good, but real life

often disrupts the plan. |

|

|

| Observing

and training shooters ranging from new, and intermediate

to advanced allows for many ideas about mechanical and

personal improvements to assist them in improving shooting

performance. Some of the best ideas to "G.I. proof"

firearms come from watching novice shooters. |

|

| How

will an inexperienced shooter force the firearm to operate

when things are going poorly for him or her? How many

times will they misload their pistol while under stress?

How will they forcibly clear malfunctions? etc. Bottom

line in the real world is the extractor will likely be

occasionally snapped over the cartridge base, whether

it is intentional or not. This is especially true during

high stress malfunction clearance, or when losing the

pistol's magazine and being forced to insert cartridges

directly into the chamber and close the slide/extractor

over their bases to at least have a single shot pistol.

If you break your extractor hook during these activities,

you have severely handicapped your pistol's operational

effectiveness. |

|

| Solution? |

|

| What's

all this hype about pivoting and/or external extractors

for the 1911? Dave Lauck has experimented with all currently

available pivoting 1911 extractor designs. It appears

that the problem they solve is related to parts installation

by semiskilled workers on production line 1911s. It is

much simpler to have workers install coil spring A, with

pin B, and extractor C, rather than have experienced workers

properly fit and adjust an internal 1911 extractor. |

|

|

|

| None

of the tested pivoting (or other) extractors have solved

the potential breakage problems related to snapping the

extractor hook over the base of a cartridge chambered

in front of the extractor hook. In fact some of these

extractors are designed in a way which makes it impossible

for the pistol to go into battery with a cartridge in

front of the hook unless you break the hook. Not good

during serious encounters. Add to this the problems of

extractor pivot pins coming loose and coil springs clogging

with contaminants and it is obvious a better solution

was needed. |

|

| Dave

Lauck's Design Solution |

|

| Dave

Lauck's design solution will work with either an internal

conventional, internal pivoting, or external pivoting

extractor. The internal conventional extractor is preferred

because it remains closer to the boreline, and it does

not require a pivot point or springs. This is an area

where the simple solution is the best solution. |

|

| Dave

Lauck's design does not change the preferred and recommended

method of 1911 operation, i.e. it is still recommended

you cycle cartridges into the chamber via the magazine.

What the new design does is drastically minimize the chances

of bending or breaking your extractor on those occasions

when the pistol is misloaded, or when a case stuck in

the chamber must be cleared immediately and the extractor

hook is intentionally snapped over the base of the stuck

case. |

|

| This

is accomplished with a redesigned leading edge on the

extractor hook. The new hook is designed to be similar

to the profile of a Tanto knife blade. This allows the

hook to be directed out and around the base of the chambered

cartridge with a drastically reduced chance of damage

or breakage. Conventional extractor hook designs receive

tremendous impact shock and often fracture or are bent

during the snap over process. The new Tanto design shape

allows for a much smoother and reliable snap over. |

|

|

|

|

| The

D&L Tanto extractor is manufactured from heat treated,

spring tempered steel for a long and reliable service

life. During the testing and development of this new extractor

design a single extractor was properly installed in a

D&L 1911 Signature Model Pistol, then improperly operated

by snapping the hook over a chambered case 5000 times.

Not only did the extractor survive with no damage, it

did not even lose its proper tension setting. This is

how smooth the Tanto profile allows the hook to snap over

chambered cases. |

|

| The

Tanto extractor can be conventionally fitted to 1911,

Series 70, and Series 80 pistol slides. A small angled

notch is required to be milled into the right rear surface

of the barrel to complete installation. |

|

| This

is an invention that is as important for 1911s as reliable

magazines are for the AR-15/M-16. It is one of those inventions

that doesn't get much operator notice because it rarely

needs attention, and it just keeps on working. Operator

level personnel often don't understand or care about the

mechanical reasons for reliability or unreliability, they

just know if something works reliably or not. It is simple:

is the component heavy duty and reliable, or not? That's

what matters to field operators. This is one such 1911

design upgrade that dramatically improves 1911 reliability

potential under all conditions and should be considered

mandatory on all serious use 1911s. |

|

Price: $60 |

|

| In

order to expedite this invention getting to end users,

licensing agreements will be considered with quality manufacturers. |

|

|

|

| 1911

Tanto Extractor Installation |

|

| Warning:

This and all other DLS products should be installed by

a skilled, competent, and experienced gunsmith familiar

with the firearm design to be worked on. Failure to install

components properly can lead to firearm failure, injury,

and/or death. |

|

| The

primary 1911 Tanto Extractor design is compatible with

the internal extractor tunnels of proper spec 1911 Series

70 and 80 pistols. Simply remove standard internal extractor

and the Tanto Extractor should fit the existing extractor

tunnel with little or no fitting. Correctly tension the

extractor until it will hold a loaded cartridge in the

breachface area. No filing on the extractor should be

required. If proper tension can't be achieved, check the

breachface dimension of the slide. On rare occasions the

breachface may be slightly oversized, and require minor

extractor modification to compensate for this problem.

Consult a more experienced 1911 gunsmith, or replace the

slide if the problem is severe. |

|

|

| The

extended leading edge of the patented Tanto Extractor

hook requires the rear of the barrel to be relieved on

the ejection port side of the pistol. This is a very simple,

but critical milling operation. After installing the extractor

and reassembling the pistol without the recoil spring,

push the slide forward and note the area of the barrel

that needs to be relieved. Keep in mind that the barrel

moves up and down while going in and out of a locked position.

This means the relief cut needs to be wider than the extractor.

A .250" end mill is just right. |

|

| Angle

mill the rear of the barrel in a manner which makes room

for the extractor hook, but minimizes chamber exposure.

Use Dykem to frequently check progress while taking off

only 002" - 003" per pass. Only make the cut

deep enough to assure the extractor hook does not touch

the barrel when the slide comes forward, or when the barrel

moves in and out of the locked position. |

|

| Professional

installation is required to assure safety and proper function.

Seek assistance if necessary. |

|

| 1911 auto pistol extractors require precise individual fitting to achieve proper function and reliability with individual firearms. All D&L Inc. components should be installed by a competent and experienced gunsmith, and thoroughly test fired for reliability prior to serious use. |

|

|

|

|